Semi-automatic soap finishing line

Ligne de finition de savon version semi-automatique

The project is to create of a soap finishing line using semi-worked products (noodles), perfumes, creams and others.

The line capacity will be between 80 to 100 kg/h and soaps will have a mass between 15 to 200 grams.

Automatic soap finishing line

Ligne de finition de savon version automatique

The project is to create a soap finishing line which is using semi-worked raw materials ( noodles ), fragrance, cream, softener, … The capacity of the line is about 200 to 2000 kg/h with soaps weighing 15 to 400 grams.

Soap finishing line for household soap

Ligne de finition de savon de ménage

Household soap manufacture is different from traditional toilet soap making. This finishing line is automatic but we use machines with a bigger capacity because the soap and the production are more important.

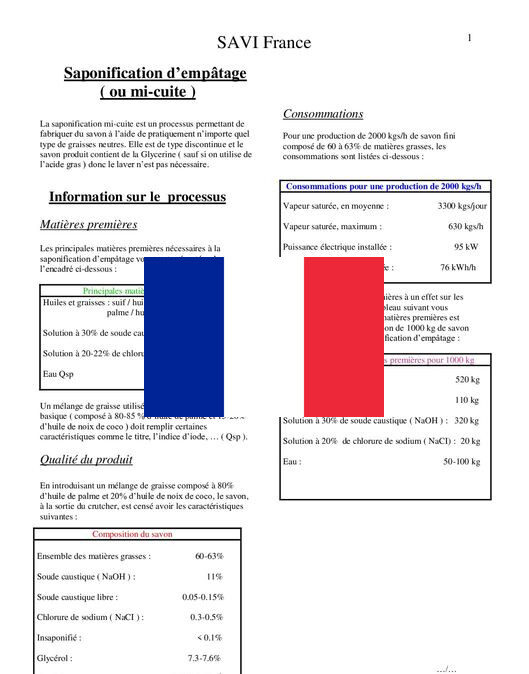

Semi-boiled saponification plant

Ligne se saponification de savon mi-cuit

Semi-boiled saponification plant is a process which allows the production of soap from any type of neutral fats. It’s discontinuous and the soap contains Glycerin, except if we use fatty acid, so no washing is necessary.

Vacuum drying line

Ligne de séchage sous vide de savon

Vacuum drying is a way to dry the soap immediately. In a dryer, soap is dried, expanded in vacuum and cooled at the same time. We recommend this process. Besides the quality of soap, cool water consumption and availability are very important in the way of drying choice.